Table of Contents

Understanding Alkyd Paint: Composition and Benefits

Alkyd paint is a type of oil-based paint that has been widely used in various applications for its durability and glossy finish. The term “alkyd” refers to the synthetic resin used as a binder in the paint, which is formed by the reaction of polyhydric alcohols with polybasic acids. This unique composition gives alkyd paint its distinct characteristics, setting it apart from other types of paint such as latex or acrylic.

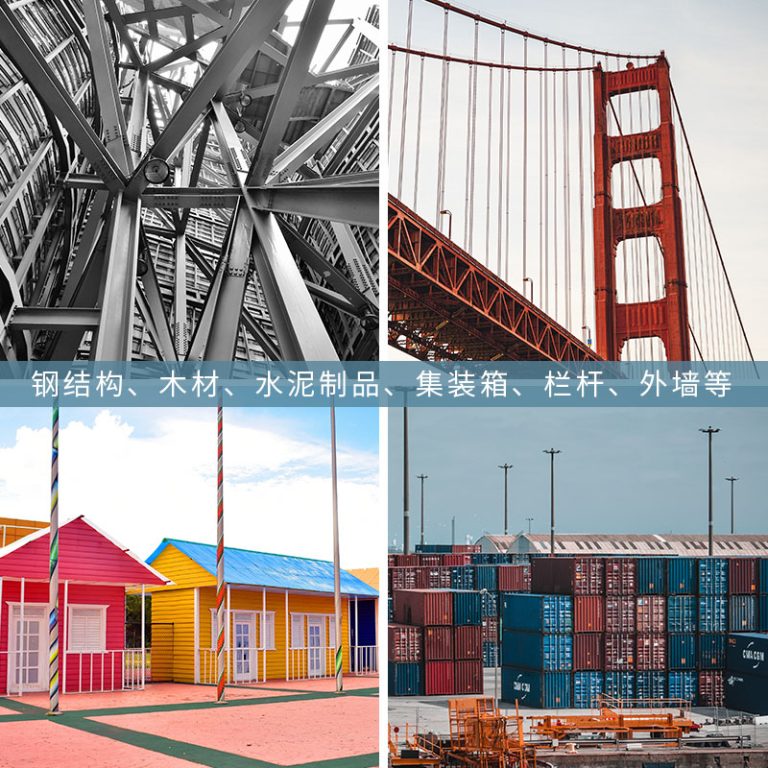

One of the primary benefits of alkyd paint is its exceptional adhesion properties. The alkyd resin in the paint provides a strong bond to a variety of surfaces, including wood, metal, and even previously painted surfaces. This makes it an ideal choice for projects that require a long-lasting finish, such as exterior house painting or furniture restoration. Additionally, alkyd paint is known for its resistance to wear and tear, making it suitable for high-traffic areas or surfaces that are frequently exposed to harsh environmental conditions.

| No. | Article Name |

| 1 | Industrial paint |

Another advantage of alkyd paint is its ability to create a smooth, glossy finish. The paint’s high level of pigment and binder allows it to flow evenly over surfaces, minimizing brush marks and providing a professional-looking result. This characteristic is particularly beneficial for projects where aesthetics are a priority, such as interior trim work or cabinetry. Furthermore, the glossy finish of alkyd paint enhances its protective qualities, as it creates a barrier that repels water and resists staining.

Despite its many benefits, alkyd paint does have some drawbacks that should be considered before use. One of the main concerns is its relatively slow drying time compared to water-based paints like latex. This can be inconvenient for projects that require multiple coats or quick completion. However, the slow drying time also allows for better leveling and a smoother finish, which can be advantageous in certain situations.

In addition to its slow drying time, alkyd paint also emits a strong odor and contains volatile organic compounds (VOCs), which can be harmful to both the environment and human health. As a result, proper ventilation is essential when working with alkyd paint, and it may not be the best choice for indoor projects where air quality is a concern. However, advancements in paint technology have led to the development of low-VOC and even VOC-free alkyd paints, which offer the same benefits with reduced environmental impact.

In conclusion, alkyd paint is a versatile and durable option for a wide range of painting projects. Its strong adhesion properties, resistance to wear and tear, and ability to create a smooth, glossy finish make it a popular choice for both professional painters and DIY enthusiasts. However, it is important to weigh the benefits against the potential drawbacks, such as slow drying time and VOC emissions, and to consider the specific requirements of the project before choosing alkyd paint. With proper application and ventilation, alkyd paint can provide a long-lasting and aesthetically pleasing finish that enhances the appearance and functionality of any surface.

Alkyd Paint Applications: Best Practices for Professional Results

Alkyd paint, a synthetic resin-based paint, is widely favored for its durability, versatility, and superior adhesion properties. It is commonly used in both interior and exterior applications, providing a hard, glossy finish that is resistant to moisture and wear. To achieve professional results when using alkyd paint, it is essential to follow best practices that ensure a smooth, even application and a long-lasting finish.

The first step in achieving optimal results with alkyd paint is surface preparation. Properly preparing the surface is crucial as it directly impacts the paint’s adhesion and overall finish. Begin by cleaning the surface thoroughly to remove any dirt, grease, or existing paint. If painting over a previously painted surface, it is important to sand it lightly to create a rough texture that will help the new paint adhere better. Additionally, any holes or cracks should be filled and sanded smooth to ensure an even surface.

Once the surface is prepared, choosing the right tools for the application is the next step. Alkyd paints are best applied using high-quality brushes or rollers designed specifically for use with oil-based paints. These tools help to achieve a smooth, professional finish without leaving brush marks or roller stipple. For larger surfaces, using a sprayer can be an efficient method, but it requires some expertise to avoid uneven coverage.

When applying alkyd paint, it is important to work in a well-ventilated area due to the strong fumes emitted by the paint. Wearing protective gear such as gloves, goggles, and a respirator mask is also recommended to safeguard against potential health hazards. Begin by applying a thin, even coat of paint, working in sections and maintaining a wet edge to avoid lap marks. Allow sufficient drying time between coats, as recommended by the manufacturer. Alkyd paint typically takes longer to dry than latex paints, so patience is key.

One of the advantages of alkyd paint is its ability to flow out smoothly, reducing the appearance of brush strokes. However, this also means that drips and sags are more likely if the paint is applied too heavily. To prevent this, it is crucial to apply the paint in thin layers and to avoid overloading the brush or roller. If a drip or sag does occur, it should be smoothed out immediately before the paint begins to set.

| No. | Product Name |

| 1 | Industrial paint |

For a professional-grade finish, it is often necessary to apply multiple coats of alkyd paint. Each coat should be allowed to dry thoroughly before the next is applied, following the manufacturer’s recommended drying times. Sanding lightly between coats can help to achieve an ultra-smooth finish and promote better adhesion of subsequent layers.

In conclusion, alkyd paint is a popular choice for both professional painters and DIY enthusiasts due to its durability and glossy finish. By following best practices such as proper surface preparation, choosing the right application tools, and applying the paint in thin, even coats, it is possible to achieve professional results that stand the test of time. With careful attention to detail and a commitment to quality, alkyd paint can provide a beautiful and long-lasting finish for a variety of surfaces.