Table of Contents

The Benefits and Applications of 95% Zinc Paint in Corrosion Protection

Title: The Benefits and Applications of 95% Zinc Paint in Corrosion Protection

In the realm of industrial coatings, the battle against corrosion is a perpetual challenge. Among the myriad of solutions, 95% zinc paint emerges as a formidable contender, offering a blend of durability and protection that is hard to surpass. This specialized paint, with its high concentration of zinc, serves as a sacrificial anode, providing galvanic protection to metal surfaces. The efficacy of this method in safeguarding structures from the relentless onslaught of corrosion is well-documented, making it a preferred choice in various industries.

The principle behind 95% zinc paint is grounded in the science of galvanic corrosion. Zinc, being more anodic than steel, will corrode preferentially when both metals are in contact and exposed to an electrolyte, such as water. This sacrificial action preserves the integrity of the underlying steel or iron, thereby extending the lifespan of the structure. The high zinc content ensures that a dense, impermeable barrier is formed upon application, which not only physically shields the surface but also electrochemically protects the substrate.

Moreover, the paint’s formulation is designed to offer excellent adhesion to the metal surface, which is critical for long-term protection. Once cured, the coating exhibits remarkable resistance to abrasion and impact, which is particularly beneficial in environments where mechanical wear is a concern. Additionally, the paint is resistant to a wide range of chemicals, making it suitable for use in harsh industrial settings where exposure to corrosive substances is a routine occurrence.

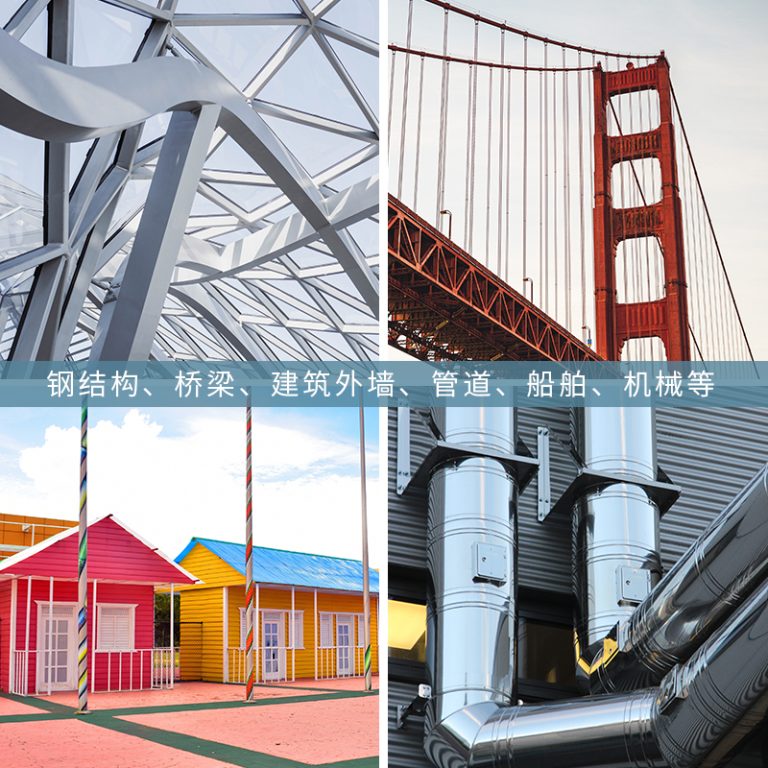

The versatility of 95% zinc paint is another of its strengths. It can be applied to a variety of surfaces, including steel structures, bridges, marine vessels, and offshore platforms. Its application is not limited to new constructions; it is equally effective when used for maintenance and repair work on existing structures. The paint can be applied by brush, roller, or spray, allowing for flexibility in addressing the specific needs of a project.

In terms of environmental impact, 95% zinc paint is a responsible choice. As regulations on volatile organic compounds (VOCs) become increasingly stringent, the industry has responded by developing formulations with lower VOC content. This not only helps in reducing environmental pollution but also improves the safety for workers applying the coating.

www.youtube.com/watch?v=kCkCI75Qvv8

| Serial Number | Product |

| 1 | Epoxy Zinc rich paint |

The initial cost of 95% zinc paint may be higher than that of conventional paints, but when considering the total lifecycle costs, it proves to be economically advantageous. The longevity of the coating reduces the frequency of maintenance and repainting, which translates to cost savings over time. Furthermore, the protection it affords can prevent catastrophic failures that could result in expensive repairs or replacements.

In conclusion, the benefits of 95% zinc paint in corrosion protection are manifold. Its superior protective qualities, coupled with its adaptability and environmental compliance, make it an invaluable asset in the fight against corrosion. Industries that have embraced this technology enjoy enhanced safety, reduced maintenance costs, and prolonged service life of their assets. As research continues to refine and improve upon this already impressive coating, its applications are likely to expand, further cementing its role as a critical component in modern corrosion protection strategies.

Comparing 95% Zinc Paint to Other Anti-Corrosive Coatings: An In-Depth Analysis

Title: 95% Zinc Paint

In the realm of anti-corrosive coatings, 95% zinc paint stands out as a formidable contender, offering robust protection against the relentless onslaught of rust and corrosion. This specialized coating, rich in metallic zinc, acts as a sacrificial anode when applied to steel, a method that has been proven to effectively shield the underlying metal from corrosive elements. To fully appreciate the merits of 95% zinc paint, it is essential to conduct an in-depth analysis and compare it with other anti-corrosive coatings available on the market.

Galvanic protection is the cornerstone of 95% zinc paint’s defensive strategy. The high concentration of zinc within the paint reacts with oxygen and moisture, forming a protective barrier of zinc oxide and zinc carbonate. This layer not only shields the steel but also corrodes in place of the steel, thereby prolonging the structural integrity of the coated object. This process, known as cathodic protection, is particularly effective in environments where steel is exposed to harsh weather conditions or corrosive chemicals.

In contrast, traditional paints and coatings primarily provide a barrier protection, which, while effective to a degree, can be compromised by scratches or damage to the coating surface. Once the barrier is breached, moisture and oxygen can reach the metal substrate, leading to rust and corrosion. These coatings rely on their adhesion to the surface to maintain their protective qualities, and any failure in this adhesion can lead to underfilm corrosion.

Epoxy coatings, another popular choice for corrosion protection, offer excellent adhesion and chemical resistance. However, they do not inherently possess the self-sacrificing properties of zinc-rich paints. While epoxies can be combined with zinc powder to enhance their protective capabilities, the resulting zinc content is typically lower than that found in 95% zinc paint, which may result in less effective cathodic protection over time.

Polyurethane coatings are lauded for their durability and resistance to UV radiation, making them a suitable topcoat to protect against environmental degradation. However, like epoxies, they do not provide cathodic protection and are often used in conjunction with zinc-rich primers to achieve comprehensive anti-corrosive performance.

It is also worth noting that the application of 95% zinc paint requires meticulous surface preparation to ensure maximum adhesion and effectiveness. The surface must be clean, free of rust, grease, and other contaminants, and often requires abrasive blasting to achieve the necessary profile for the zinc particles to adhere properly. This level of preparation is critical to the success of the coating and is a step that cannot be overlooked.

The longevity of 95% zinc paint is another aspect that merits attention. When applied correctly, it can protect steel for decades, reducing the need for frequent maintenance and recoating. This long-term protection is not only cost-effective but also environmentally beneficial, as it reduces the amount of waste and pollutants associated with repainting and maintenance.

| No. | Product Name |

| 1 | Industrial paint |

In conclusion, 95% zinc paint offers a superior level of protection against corrosion when compared to other coatings. Its ability to provide cathodic protection through galvanic action sets it apart from barrier-type coatings and makes it an ideal choice for environments where steel is exposed to severe corrosive forces. While the initial cost and application requirements may be higher than some alternatives, the long-term benefits of durability and reduced maintenance make 95% zinc paint a wise investment for those seeking to preserve the integrity of their steel structures.