Table of Contents

Advantages of Waterborne Fluorocarbon Paint in Exterior Applications

Waterborne fluorocarbon paint has emerged as a game-changer in exterior applications, revolutionizing the way we approach surface protection and aesthetics. This innovative coating offers a myriad of advantages over traditional solvent-based paints, making it a preferred choice for architects, contractors, and homeowners alike.

One of the primary advantages of waterborne fluorocarbon paint is its superior durability. Unlike solvent-based paints, which tend to degrade over time due to exposure to harsh weather conditions, waterborne fluorocarbon paint forms a resilient barrier against moisture, UV rays, and chemical pollutants. This enhanced durability translates to longer-lasting protection for exterior surfaces, reducing the frequency of repainting and maintenance costs.

Moreover, waterborne fluorocarbon paint boasts exceptional color retention properties. Thanks to its advanced formulation, this paint maintains its vibrant hues even after prolonged exposure to sunlight and environmental stressors. This means that buildings and structures coated with waterborne fluorocarbon paint retain their aesthetic appeal for years to come, without fading or discoloration.

In addition to its durability and color retention, waterborne fluorocarbon paint offers superior environmental credentials. Unlike solvent-based paints, which contain high levels of volatile organic compounds (VOCs) and harmful chemicals, waterborne fluorocarbon paint is low in VOCs, making it a more eco-friendly option. By choosing waterborne fluorocarbon paint for exterior applications, individuals can reduce their carbon footprint and contribute to a healthier environment.

Furthermore, waterborne fluorocarbon paint facilitates ease of application and cleanup. Its water-based formulation allows for smooth and even coverage, resulting in a professional finish with minimal effort. Additionally, cleanup is hassle-free, as waterborne fluorocarbon paint can be easily removed from brushes, rollers, and other painting equipment with water, eliminating the need for harsh solvents.

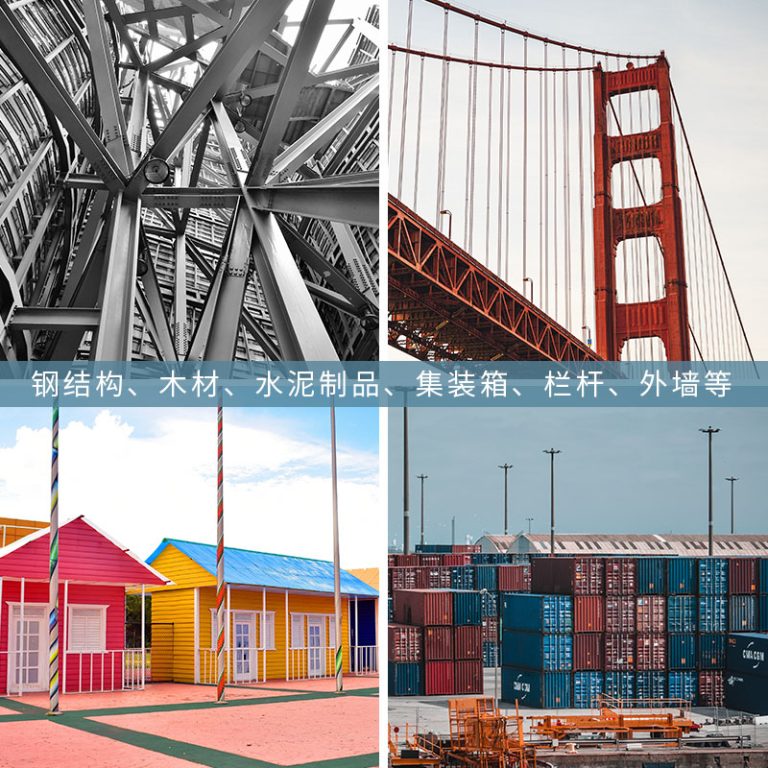

Another significant advantage of waterborne fluorocarbon paint is its versatility. This paint can be applied to a wide range of exterior surfaces, including concrete, metal, wood, and stucco, providing comprehensive protection for various architectural elements. Whether used on residential homes, commercial buildings, or industrial facilities, waterborne fluorocarbon paint delivers exceptional performance and aesthetics across diverse applications.

Moreover, waterborne fluorocarbon paint offers enhanced resistance to stains and graffiti. Its non-stick surface prevents dirt, grime, and pollutants from adhering to the substrate, making it easier to clean and maintain. Additionally, graffiti can be quickly and effectively removed from surfaces coated with waterborne fluorocarbon paint, preserving the integrity of the underlying substrate.

In conclusion, waterborne fluorocarbon paint represents a significant advancement in exterior coatings, offering unparalleled durability, color retention, environmental sustainability, ease of application, versatility, and resistance to stains and graffiti. By harnessing the benefits of this innovative paint technology, architects, contractors, and homeowners can achieve long-lasting protection and aesthetic excellence for their exterior surfaces. As the demand for sustainable and high-performance coatings continues to rise, waterborne fluorocarbon paint stands out as a reliable solution for the challenges of modern architecture and construction.

Environmental Benefits of Using Waterborne Fluorocarbon Paint

Waterborne fluorocarbon paint, a type of coating that has gained prominence in various industries, offers a plethora of environmental benefits. As the world increasingly prioritizes sustainability, the adoption of eco-friendly alternatives becomes imperative. In this context, waterborne fluorocarbon paint emerges as a compelling solution, combining performance with environmental consciousness.

One of the primary advantages of waterborne fluorocarbon paint lies in its composition. Unlike traditional solvent-based paints, which contain volatile organic compounds (VOCs) harmful to both human health and the environment, waterborne fluorocarbon paints use water as the primary solvent. This drastically reduces VOC emissions during application and drying, thereby minimizing air pollution and contributing to improved air quality.

Furthermore, the use of waterborne fluorocarbon paint aligns with regulatory standards aimed at curbing environmental degradation. Many countries have stringent regulations regarding VOC emissions from industrial processes, including painting. By opting for waterborne fluorocarbon paint, industries can comply with these regulations more easily, avoiding fines and penalties while reducing their ecological footprint.

| No. | Product |

| 1 | Industrial paint |

Moreover, the production process of waterborne fluorocarbon paint generally consumes less energy compared to solvent-based alternatives. This aspect is crucial in the context of climate change, where reducing energy consumption is pivotal for mitigating greenhouse gas emissions. By choosing waterborne fluorocarbon paint, industries can contribute to energy conservation efforts, fostering a more sustainable future.

In addition to its environmental benefits during production and application, waterborne fluorocarbon paint also offers advantages in terms of durability and longevity. Due to its advanced formulation, this type of paint exhibits excellent adhesion, abrasion resistance, and color retention properties. As a result, surfaces coated with waterborne fluorocarbon paint require less frequent repainting, reducing the overall consumption of resources and waste generation.

Furthermore, the durability of waterborne fluorocarbon paint translates into extended maintenance intervals, lowering the need for frequent touch-ups and refurbishments. This not only saves time and labor but also minimizes the use of additional coatings and associated materials, contributing to resource conservation and waste reduction efforts.

Transitioning to waterborne fluorocarbon paint also fosters innovation within the coatings industry. Manufacturers are continually investing in research and development to improve the performance and sustainability of waterborne formulations, driving technological advancements and fostering a culture of environmental responsibility. This ongoing innovation paves the way for the development of even more eco-friendly coatings in the future, further enhancing the sustainability of the industry.

Moreover, the adoption of waterborne fluorocarbon paint sets a positive example for other sectors, demonstrating that environmental responsibility and business success are not mutually exclusive. By showcasing the viability of sustainable alternatives, industries can inspire broader adoption across various domains, leading to a more widespread transition towards eco-friendly practices.

In conclusion, waterborne fluorocarbon paint offers a myriad of environmental benefits, ranging from reduced VOC emissions and energy consumption to enhanced durability and innovation within the coatings industry. By choosing waterborne fluorocarbon paint, industries can align their operations with sustainability goals, contributing to a cleaner environment and a brighter future for generations to come.

Tips for Applying Waterborne Fluorocarbon Paint for Optimal Results

Waterborne fluorocarbon paint has gained significant popularity in recent years due to its superior durability, environmental friendliness, and ease of application. Whether you’re a professional painter or a DIY enthusiast, understanding the nuances of applying waterborne fluorocarbon paint can make a substantial difference in achieving optimal results. In this article, we’ll explore some essential tips to help you get the most out of this advanced coating technology.

First and foremost, proper surface preparation is paramount when working with waterborne fluorocarbon paint. Begin by thoroughly cleaning the surface to remove any dirt, grease, or contaminants that could interfere with adhesion. Depending on the substrate, this may involve washing with soap and water, using a degreaser, or employing more aggressive cleaning methods such as sanding or power washing. Additionally, ensure that the surface is completely dry before applying the paint to prevent adhesion issues and promote optimal curing.

Once the surface is clean and dry, it’s time to consider priming. While waterborne fluorocarbon paints are known for their excellent adhesion properties, applying a primer can further enhance adhesion, promote uniformity, and improve overall durability. Choose a primer specifically formulated for use with waterborne fluorocarbon paints, and follow the manufacturer’s instructions for application and drying times.

When it comes to applying waterborne fluorocarbon paint, proper technique is key to achieving a smooth, flawless finish. Start by selecting high-quality brushes, rollers, or spray equipment suitable for water-based coatings. Avoid using brushes or rollers with stiff bristles, as they can leave visible brush marks or stippling on the surface. If using a sprayer, adjust the settings to achieve the desired spray pattern and atomization for optimal coverage.

Before applying the paint, thoroughly mix it according to the manufacturer’s instructions to ensure uniformity and consistency. Stirring or shaking the paint can help distribute any settling or separation that may have occurred during storage. Additionally, strain the paint through a fine mesh filter to remove any impurities or particles that could mar the finish.

When applying waterborne fluorocarbon paint, aim for thin, even coats to prevent runs, drips, or sagging. Work methodically, starting from the top of the surface and progressing downward to minimize drips and ensure uniform coverage. Avoid overworking the paint, as excessive brushing, rolling, or spraying can disrupt the drying process and result in an uneven finish.

After applying the first coat, allow sufficient drying time before applying additional coats. Check the manufacturer’s recommendations for the optimal drying and recoat times based on environmental conditions such as temperature and humidity. Inadequate drying time between coats can lead to poor adhesion, wrinkling, or other defects.

Finally, proper care and maintenance are essential to ensure the longevity and performance of waterborne fluorocarbon paint. Once the paint has fully cured, avoid exposing it to harsh chemicals, abrasive cleaners, or excessive moisture, as these can compromise the finish over time. Regular cleaning with mild soap and water can help preserve the paint’s appearance and protect it from degradation.

| Serial Number | Product |

| 1 | Epoxy Zinc rich paint |

In conclusion, mastering the art of applying waterborne fluorocarbon paint requires attention to detail, proper preparation, and skillful execution. By following these tips and techniques, you can achieve professional-quality results and enjoy the numerous benefits of this advanced coating technology.