Table of Contents

Benefits And Applications Of Alkyd Resin Paint In Industrial Coatings

Alkyd resin paint is a popular choice in the industrial coatings sector due to its unique properties and versatile applications. This type of paint is synthesized from polyols, acids, and other chemical compounds, resulting in a durable and resilient finish. The benefits of alkyd resin paint are numerous, making it an ideal solution for a wide range of industrial needs.

| Serial Number | Commodity Name |

| 1 | Epoxy Zinc rich paint |

One of the primary advantages of alkyd resin paint is its exceptional durability. The chemical structure of alkyd resins allows them to form strong, cross-linked networks when cured, providing a tough and long-lasting protective layer. This makes alkyd resin paint highly resistant to wear and tear, as well as environmental factors such as moisture, UV radiation, and temperature fluctuations. As a result, surfaces coated with alkyd resin paint are less likely to degrade over time, reducing the need for frequent maintenance and repainting.

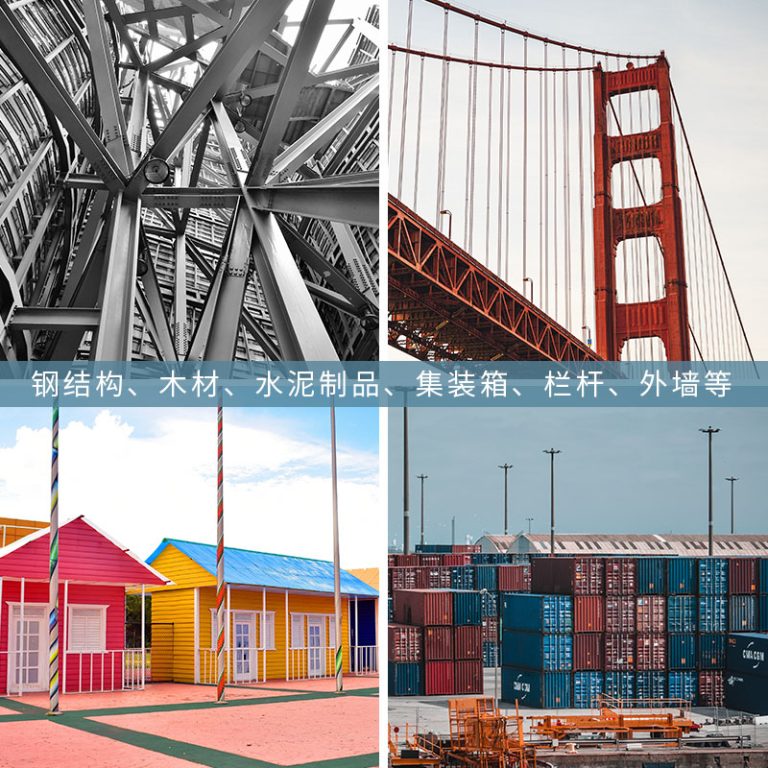

In addition to its durability, alkyd resin paint also offers excellent adhesion properties. It can bond effectively to a variety of substrates, including metal, wood, and concrete. This strong adhesion ensures that the paint remains firmly attached to the surface, preventing peeling and flaking. The ability to adhere well to different materials makes alkyd resin paint a versatile option for industrial applications, where coatings are often required on diverse surfaces.

Another significant benefit of alkyd resin paint is its aesthetic appeal. The paint is available in a wide range of colors and finishes, allowing for customization according to specific design requirements. The high-gloss finish that can be achieved with alkyd resin paint enhances the visual impact of the coated surfaces, making them more attractive and professional-looking. This is particularly important in industries where appearance plays a crucial role, such as automotive manufacturing and consumer goods production.

Furthermore, alkyd resin paint is known for its ease of application. It can be applied using various methods, including brushing, rolling, and spraying, making it convenient for different industrial processes. The paint also has a relatively fast drying time compared to other types of coatings, which helps to speed up production cycles and reduce downtime. This efficiency in application and curing is essential in fast-paced industrial environments where time is a critical factor.

The versatility of alkyd resin paint extends to its applications in various industrial sectors. It is commonly used in the automotive industry for coating vehicle bodies and parts, providing both protection and an aesthetically pleasing finish. In the construction industry, alkyd resin paint is used to coat structural steel and other building materials, enhancing their resistance to corrosion and weathering. Additionally, the paint is employed in the production of machinery and equipment, where it serves as a protective layer against mechanical wear and chemical exposure.

In conclusion, alkyd resin paint offers a range of benefits that make it a preferred choice for industrial coatings. Its durability, strong adhesion, aesthetic qualities, ease of application, and versatility in use contribute to its widespread adoption across various industries. Whether it is protecting automotive parts, enhancing the appearance of buildings, or safeguarding machinery, alkyd resin paint provides an effective and reliable solution for diverse industrial coating needs.

Comparing Alkyd Resin Paint With Other Types Of Paints For Home Renovation Projects

Alkyd resin paint, a popular choice for home renovation projects, offers a unique set of characteristics that distinguish it from other types of paints. This oil-based paint is known for its durability, smooth finish, and resistance to wear and tear, making it an ideal option for areas that experience high traffic or exposure to the elements. When comparing alkyd resin paint to other paints, it is important to consider factors such as application, drying time, and overall performance to determine the best fit for specific renovation needs.

One of the primary advantages of alkyd resin paint is its exceptional durability. The paint forms a hard, protective layer that resists chipping, cracking, and peeling, which is particularly beneficial for surfaces that are subject to frequent use or harsh conditions. This characteristic sets alkyd resin paint apart from latex paints, which are water-based and generally less resistant to wear and tear. While latex paints are easier to clean up and have a quicker drying time, they may not provide the same level of protection and longevity as alkyd resin paints.

In terms of application, alkyd resin paint requires more careful handling compared to other types of paints. It typically has a stronger odor and necessitates the use of mineral spirits or paint thinner for cleanup. Additionally, brushes and other tools used with alkyd resin paint need to be cleaned immediately after use to prevent the paint from hardening and rendering the tools unusable. Despite these challenges, many professionals and DIY enthusiasts prefer alkyd resin paint for its smooth, self-leveling properties that result in a high-quality finish with fewer brush marks.

www.youtube.com/watch?v=kCkCI75Qvv8

Another consideration when comparing alkyd resin paint to other paints is the drying time. Alkyd resin paint takes longer to dry than latex paint, which can be an inconvenience for projects that require multiple coats or have tight timelines. However, the slower drying time allows for a more even application and reduces the likelihood of visible brush strokes, contributing to a more polished final appearance. This trade-off between drying time and finish quality is an important factor to weigh when deciding on the right type of paint for a renovation project.

| Serial Serial Number | Product |

| 1 | Epoxy Zinc rich paint |

Performance in different environmental conditions is also a key aspect to consider. Alkyd resin paint performs exceptionally well in areas with high humidity or fluctuating temperatures, making it a suitable choice for exterior surfaces or rooms like kitchens and bathrooms. In contrast, other paints, such as acrylics, may not hold up as well under similar conditions, potentially leading to premature fading or degradation.

Ultimately, the choice between alkyd resin paint and other types of paints depends on the specific requirements of the home renovation project. Factors such as the desired durability, finish quality, application process, drying time, and environmental resistance all play a role in determining the most appropriate paint. By carefully evaluating these aspects, homeowners and renovators can make an informed decision that ensures both the aesthetic appeal and longevity of their renovation efforts. In conclusion, alkyd resin paint offers a robust and attractive option for those looking to achieve a professional-grade finish that stands the test of time.