Table of Contents

Benefits And Uses Of Alkyd Paint In Various Industries

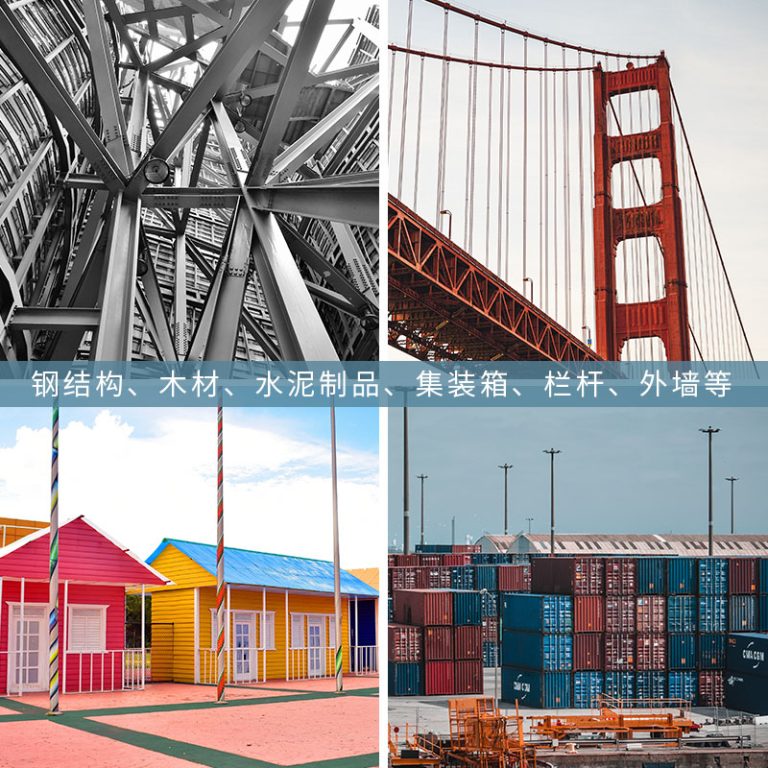

Alkyd paint, a synthetic resin-based paint, has been widely used in various industries due to its unique properties and benefits. This type of paint is known for its durability, versatility, and superior adhesion, making it an ideal choice for both indoor and outdoor applications. In this article, we will explore the benefits and uses of alkyd paint across different sectors, highlighting its significance in enhancing the quality and longevity of various projects.

One of the primary advantages of alkyd paint is its exceptional durability. Unlike other types of paint, alkyd paint forms a hard, protective film when it dries, which helps to resist wear and tear. This makes it particularly suitable for high-traffic areas and surfaces that are frequently exposed to harsh environmental conditions. As a result, industries such as construction and manufacturing often rely on alkyd paint to coat surfaces that require robust protection, such as metal structures, machinery, and equipment.

| No. | Name |

| 1 | Industrial paint |

Furthermore, alkyd paint is known for its excellent adhesion properties. It can adhere well to a wide range of surfaces, including wood, metal, and even previously painted surfaces. This versatility allows it to be used in various applications, from painting residential homes to industrial facilities. The strong bond that alkyd paint forms with the substrate ensures that the paint does not peel or flake easily, thereby extending the lifespan of the painted surface.

Another significant benefit of alkyd paint is its resistance to moisture and chemicals. This characteristic is particularly important in industries where surfaces are regularly exposed to water, oils, or chemicals. For example, in the marine industry, alkyd paint is often used to coat ships and boats to protect them from the corrosive effects of saltwater and harsh weather conditions. Similarly, in the automotive industry, alkyd paint is used to provide a durable finish on vehicles, protecting them from road chemicals and environmental pollutants.

In addition to its protective qualities, alkyd paint also offers aesthetic benefits. It is available in a wide range of colors and finishes, allowing for creative and attractive designs. The paint’s ability to retain its color and gloss over time ensures that surfaces remain visually appealing, even after prolonged exposure to sunlight and other degrading factors. This makes alkyd paint a popular choice in industries where appearance is important, such as furniture manufacturing and interior design.

Moreover, alkyd paint is relatively easy to apply and can be used with various application methods, including brushing, rolling, and spraying. This flexibility in application makes it convenient for both professional painters and DIY enthusiasts. Additionally, the paint’s quick-drying properties help to reduce project completion times, which is a critical factor in fast-paced industries.

In conclusion, alkyd paint serves as a versatile and reliable solution in numerous industries, offering a combination of durability, adhesion, resistance, and aesthetic appeal. Its ability to withstand harsh conditions and maintain its integrity over time makes it an invaluable asset in construction, manufacturing, marine, automotive, and many other sectors. By choosing alkyd paint for their projects, professionals can ensure long-lasting protection and an attractive finish, ultimately enhancing the value and functionality of their work.

Comparing Alkyd Paint With Other Types Of Paints

Alkyd paint, a type of oil-based paint, has been a popular choice for various painting projects due to its durability and glossy finish. It is composed of an alkyd resin binder, which is a synthetic polymer derived from polyols and dicarboxylic acids or their anhydrides. This unique composition gives alkyd paint its distinct characteristics, setting it apart from other types of paints available in the market.

When comparing alkyd paint with other types of paints, such as latex or acrylic, several key differences become apparent. Firstly, alkyd paint is known for its exceptional adhesion properties. This makes it an ideal choice for surfaces that require a strong bond, such as metal or wood. The paint’s ability to adhere well to a variety of surfaces ensures that it provides long-lasting protection and maintains its aesthetic appeal over time.

In contrast, latex paint, which is water-based, may not adhere as strongly to certain surfaces. While latex paint is easier to clean up and emits fewer volatile organic compounds (VOCs), it may not be as durable as alkyd paint, especially in high-traffic areas or on surfaces exposed to harsh weather conditions. Additionally, latex paint tends to dry faster than alkyd paint, which can be both an advantage and a disadvantage depending on the specific requirements of the painting project.

Another significant difference between alkyd paint and other types of paints is its finish. Alkyd paint typically provides a high-gloss finish that is both attractive and resistant to wear and tear. This glossy finish not only enhances the appearance of the painted surface but also provides an additional layer of protection against moisture, UV rays, and other environmental factors. On the other hand, acrylic paint, which is also water-based, offers a more matte finish. While acrylic paint is known for its color retention and resistance to fading, it may not provide the same level of gloss and protection as alkyd paint.

| Number | Product Name |

| 1 | Fluoracarbon finish paint |

Furthermore, the drying time of alkyd paint is longer compared to latex and acrylic paints. This extended drying time allows for a smoother and more even application, reducing the likelihood of brush marks and imperfections. However, this can also be a drawback in situations where a quick turnaround is needed, as the longer drying time may delay subsequent steps in the painting process.

In terms of environmental impact, alkyd paint has traditionally been associated with higher levels of VOCs, which can contribute to air pollution and pose health risks. However, advancements in paint technology have led to the development of low-VOC and VOC-free alkyd paints, which offer the same benefits as traditional alkyd paints while minimizing their environmental impact.

In conclusion, alkyd paint serves as a robust and versatile option for various painting projects, offering superior adhesion, durability, and a glossy finish. While it may have some drawbacks, such as longer drying times and potential environmental concerns, recent innovations have addressed these issues, making alkyd paint a competitive choice in comparison to other types of paints. Whether for indoor or outdoor use, on wood, metal, or other surfaces, alkyd paint provides a reliable and attractive solution for achieving long-lasting and visually appealing results.

Tips For Proper Application And Maintenance Of Alkyd Paint

Alkyd paint, a synthetic resin-based paint, is widely used for its durability and glossy finish. It is commonly used in both residential and commercial settings for surfaces that require a tough, long-lasting coat. Alkyd paint is particularly effective for areas that experience high traffic or exposure to the elements, making it an ideal choice for doors, trim, cabinets, and outdoor fixtures.

When applying alkyd paint, it is essential to follow specific guidelines to ensure optimal results. First and foremost, surface preparation is key. The surface should be clean, dry, and free of any grease, dust, or rust. Any loose or peeling paint should be removed, and glossy surfaces should be sanded to provide a better surface for the paint to adhere to. Priming the surface with an appropriate primer is also recommended to enhance the paint’s adhesion and overall durability.

Once the surface is properly prepared, it is important to choose the right tools for application. Alkyd paint can be applied using a brush, roller, or sprayer, depending on the size and nature of the project. When using a brush or roller, it is advisable to use high-quality tools that are specifically designed for use with oil-based paints. This will help achieve a smooth, even finish without brush marks or roller stipple.

The application technique is also crucial when working with alkyd paint. It is recommended to apply the paint in thin, even coats, allowing sufficient drying time between coats. Alkyd paint typically has a longer drying time compared to latex paints, so patience is necessary. Avoiding heavy application will prevent runs and sags, ensuring a professional-looking finish.

In terms of maintenance, alkyd paint is relatively low-maintenance once it is fully cured. However, regular cleaning and touch-ups may be necessary to keep the painted surfaces looking their best. For cleaning, use a mild detergent and water solution, and avoid abrasive cleaners that can damage the paint’s surface. If the paint becomes chipped or scratched, touch-ups can be done using the same paint and application method used initially.

It is also important to note that alkyd paint, being oil-based, requires careful handling and disposal. Proper ventilation is necessary during application to avoid inhaling fumes, and brushes and tools should be cleaned with mineral spirits or paint thinner. Leftover paint and empty containers should be disposed of in accordance with local regulations to minimize environmental impact.

In conclusion, alkyd paint serves as a robust and versatile option for various painting projects, offering a durable and attractive finish. By adhering to proper application techniques and maintenance practices, one can ensure that the painted surfaces remain in excellent condition for years to come. Whether you are painting interior trim or exterior fixtures, alkyd paint provides the resilience and aesthetic appeal needed for high-quality, long-lasting results.